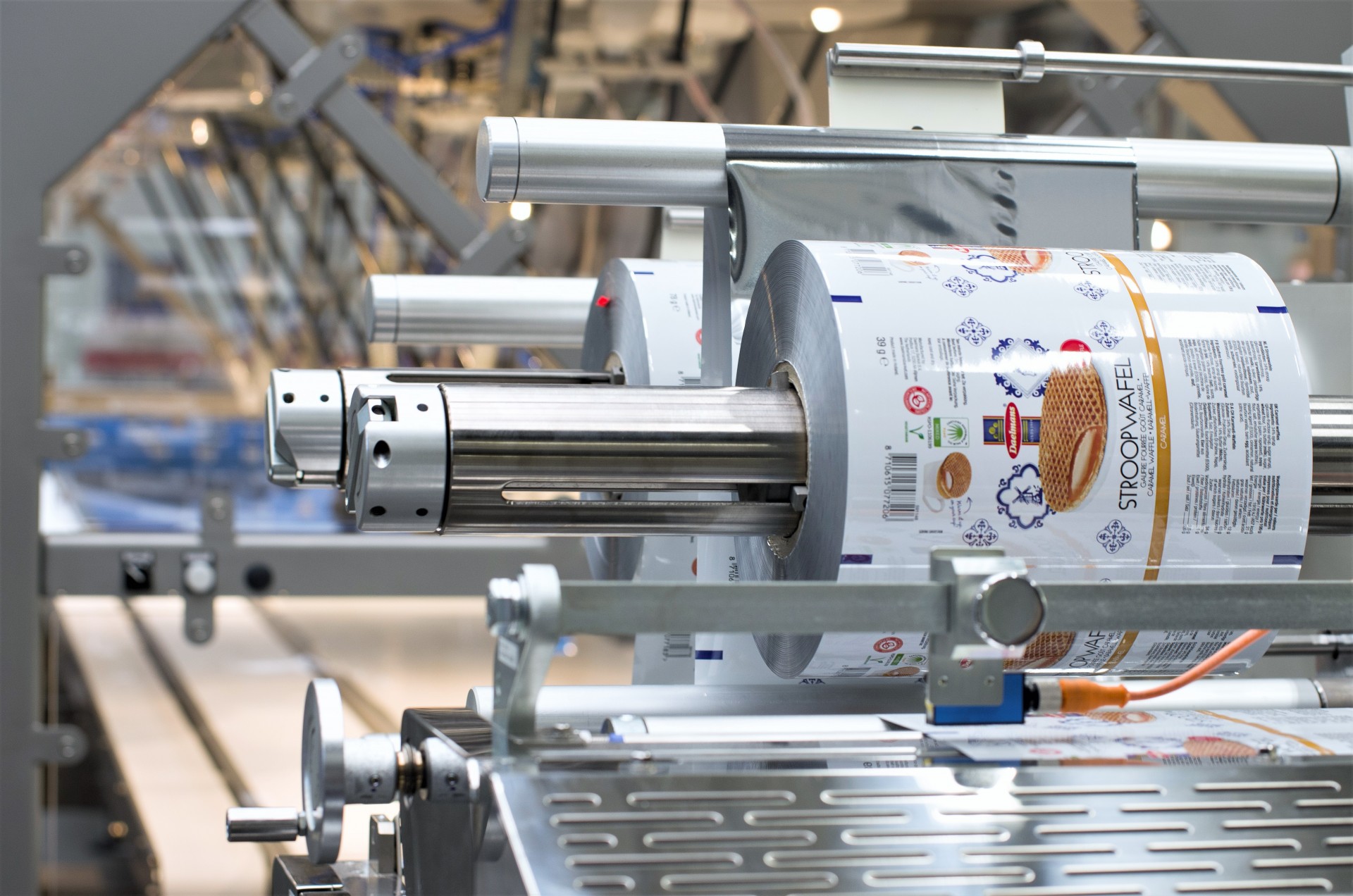

Flow packer packaging machinery

Flow packer: quick and hygienic packaging machine

A flow packer is the ideal filling and sealing machine for a smooth and efficient process for all products that must be packed horizontally. Using the flow packer, packaging is formed by foil from a role, which is wrapped around the product and sealed. The flow packer packs food quickly, hygienically, presentably and moreover the shelf-life is extended. Also for nonfood, the flow packer is the best packaging-solution in many a situation. The packaging machine can be flexibly adjusted to the relevant product and the packaging requirements.

Stand-alone flow packer or integrated in the packaging line

A flow packer can be installed as a stand-alone packaging machine, but can also excellently serve as part of a complete packaging line. Depending on your products, processes and wishes, we develop the ideal solution for you, including infeed system, transport conveyors and control software. Of course, during the development of each flow packer we fully consider the highest hygiene-requirements and HACCP-standards: each flow packer can be easily and entirely cleaned, requires little maintenance and has a long life-span.

Back seal flowpacker

For delicate or individual products

In case of the back seal flow packer, the foil is supplied from underneath: the foil carries the product. The back seal flow packer is very suitable for airproof sealing of delicate products, like tortillas, cheese and pancakes. But also for the packaging of individual products, like screws, tissues, etc., the back seal flow packer is the ideal packaging machine.

Rotary/box motion flow packer

For quick or vacuum packing.

The rotary flow packer is ideal for rapidly packing small products like candies. Speed and hygiene are the keywords for the rotary flow packer. The box motion flow packer is ideal for packaging in modified atmosphere of, for example chees products, meats and other perishable foods. Both the rotary and the box motion flow packer are structured to client specification.

Attachless infeed flow packer

Infeed by belts instead of chains

The classic flow packer infeed system operates on chain-transport. Usually this works excellently, but for some products, attachless infeed is recommended. A great advantage is that the products can be placed on the conveyor at irregular distances. The distance is automatically adjusted, so the products end up at the flow packer with the right distance between them.

Pictures of machines

Rotary Fuji Flowpacker

- 500 products a/min.

- up to widths of 500mm

Boxmotion Fuji Flowpacker

Refurbished Flowpackers