Trayloaders/Traypackers

Tray loaders/tray packer for fully automated loading of trays

Tray loaders or tray packers are used for quick and automated loading of plastics, polystyrene or cardboard trays or boxes. A pick & place-arm is used to pick up the products with a vacuum cup. Subsequently they are put down on the transport conveyor, where they are placed into a tray or box. Products that are packed by use of a tray, could be, for example, bakery products, chocolates, fruit, vegetables, etc. The tray packers are controlled electronically and by computers. The stability of the quantities per package is guaranteed via a servo-controlled system.

Tubo-filler for filling causing little breakage in case of vibration or heights

A tray packer variant is the tubo-filler, used for the filling of products into tubos or trays with as little breakage as possible, caused by vibrations or too high drop heights. With this, the tubo-filler, products can be filled perfectly, in terms of weight and quantity.

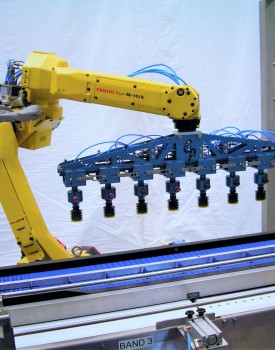

Robot tray loader/tray packer

Fully automatic loading of trays

Regarding a tray loader with robotics, the products are picked up and loaded by a pick and place-arm. Robotics guarantee reliability, efficiency and flexibility. Automation of tray loading will immediately result in higher speeds and efficiency. Furthermore, health and safety and hygiene requirements are easily complied with, using robotics applications.

Conventional tray loader/tray packer

Multi-useable for loading of trays

A conventional tray loader also takes care of loading of trays and boxes. Important features of a tray loader – either with robotics or

conventional – are the high capacity and the multi-deployability, for both single and multiple products. Cleaning of a tray loader is done quickly and very hygienically.